Simplification of enameling processes and/or equipment may result in :

- Improved surface quality

- Reduced enameling cost

- Shorter process time

- Faster process feedback

- Reduction of factory space

- Saving energy

Please find below some practical examples.

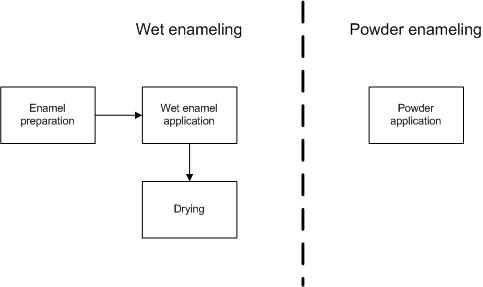

I – Conversion of application method

Traditional wet enameling comprises of at least 3 process steps; Enamel preparation, enamel application and drying.

Switching to powder enamel would eliminate enamel preparation and drying, which equals to 66% of the process stages with wet enameling.

Above shown conversion of application method has many benefits, provided your product is suitable for this technology.

Are my products suitable for powder enameling?

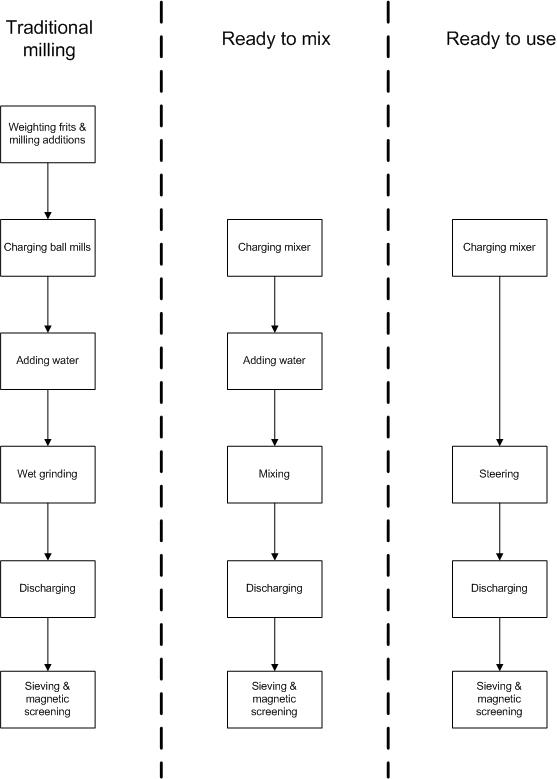

II – Elimination of in-house milling

Traditional wet milling is a time-consuming & tricky process, where it is easy to make a little mistake with significant consequences.

Switching to ready-to-mix or ready-to-use enamels will reduce the chance of such error and reduce also the total time for enamel preparation considerably.