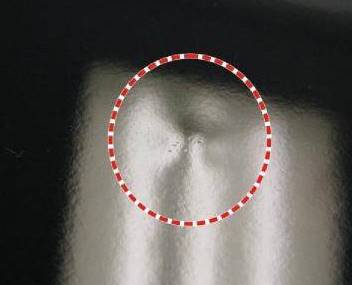

Lumps are common enamel defects, which are characterised by rounded raised areas with typically a diameter between 3 to 12 mm.

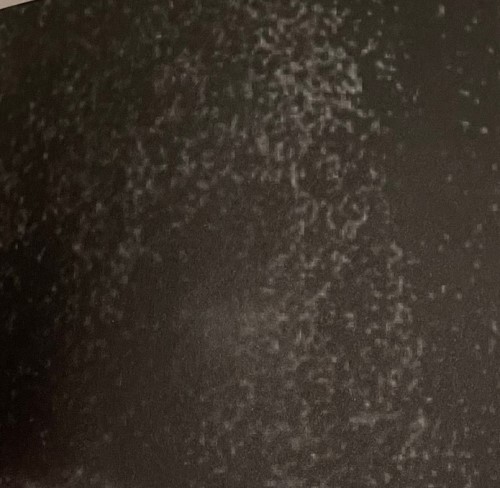

Scaling

Scaling is a common enameling defect, which is caused by contamination with materials with a higher melting temperature than enamel.

Identification of enameling defects

Identifying the correct type of enamel defect is the first & perhaps most important step when troubleshooting industrial enameling processes. Analyzing enameling defects with digital...

Blisters

Blisters are a common enamel defect, which is characterized by appearance of circular holes & bubbles in a cooled enameled surface.

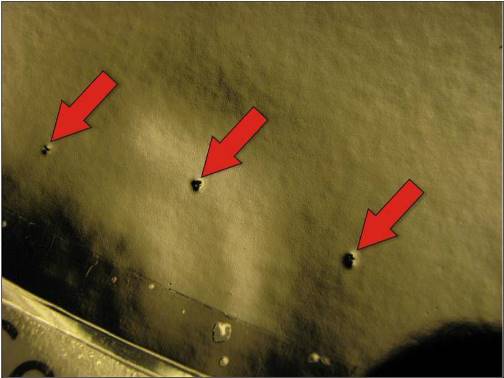

Fishscaling of porcelain/vitreous enamel coatings

Fishscaling is an enameling defect, which is characterized by small enamel particles chipping off.

UNI 11734 : Determining fish-scale susceptibility of enameling steel

The Italian National Unification institute has published UNI 11734 as of December 6, 2018. This standard specifies a method for measuring the hydrogen diffusion coefficient in order...

Enameling cost reduction

Porcelain (vitreous) enameling is a relative complex coating process with many steps & dito variables. This complexity makes it very well suited for continuous improvement...

Troubleshooting enameling defects

Resolving enamel defects during an industrial manufacturing process requires a structured three steps approach. Step I Identify the right defect. This may sound silly, but...