Visited the Tecnargilla 2018 show in Rimini some weeks ago and saw there a new application method called “Steam Spraying”.

The manufacturer of this spray equipment reported that atomizing coating materials with steam instead of compressed air has the following advantages :

- Reduced bounce back and more homogeneous film build thanks to softer application

- Significant reduction of total compressed air consumption

- Shorter drying time thanks to less residual moisture

- Reduced noise emission thanks to reduced pressure of fan pattern

- Improved transfer efficiency reduces over-spray and hence less cleaning & maintenance efforts

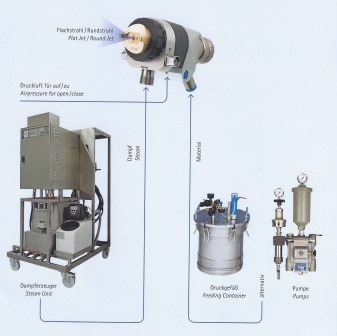

Typically a “Steam Spraying” system consists of the following components :

- Automatic spray gun

- Feeding container or double action pump

- Mobile steam generator

This technology has already been successfully introduced at various ceramic manufacturers and is currently also tested at some industrial enamelists.

Please feel free to contact DTC for more information about this innovative application method for wet enamel slip.