Introduction

New enameling plant projects are usually very complex and require considerable capital investments.

Often companies don’t have the necessary experience, resources and/or up-to-date enameling process & equipment knowledge to complete a large enameling project successfully within planning, budget & specifications.

Implementation risks may be greatly reduced by early involvement of independent subject matter experts and adopting professional project management.

Table of contents

Enameling plant projects

Industrial enameling is a relative complex process compared to many other manufacturing processes and capital investments for new enameling plants range from less than 1.0 million USD to more than 10 million USD.

Important decisions must be made at the beginning of each enameling plant project and those decisions may have far reaching consequences.

Implementation risks for enameling plant projects may range from “delayed start-up of production” or “higher enameling cost than expected” up to “failing to achieve proper enamel coating quality” or “inability to reach targeted production” and can have a detrimental effect on the Return On Investment of your project.

Often companies don’t have experienced resources in-house to manage such large projects and/or are lacking up-to-date knowledge to select the best suitable enameling process(es) and/or correctly specify & evaluate the characteristics of the enameling equipment.

Ditmer Enameling Technology is specialized in setting-up enameling plants and may provide the necessary know-how, independent advice, hands-on support & professional project management, based on almost 40 years of experience. Click here for our reference list.

In some cases, we were even contracted to deliver the entire enameling plant as a (modified) turnkey project.

Project management

Over the years we developed & enhanced our project management methodology, which includes the following elements :

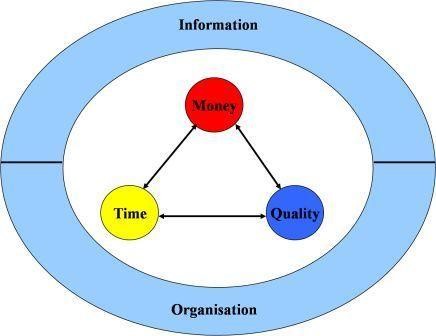

Balanced project approach

It is important to maintain a healthy balance between project planning, budget & quality, while ensure an adequate organization and information system.

We see unfortunately regularly that enameling plant projects, which focus too much on either budget or planning, fail to achieve the original project objectives and in consequence enamellers are stuck with a disappointing enameling process and/or equipment performance for many years.

Project phasing

By thinking in terms of project phases, we can ensure that the deliverables produced at the end of each phase meet their purpose, and that project team members are properly prepared for the next phase.

We typically breakdown the life cycle of a standard project into four phases:

- Initiation

- Preparation

- Execution

- Closure

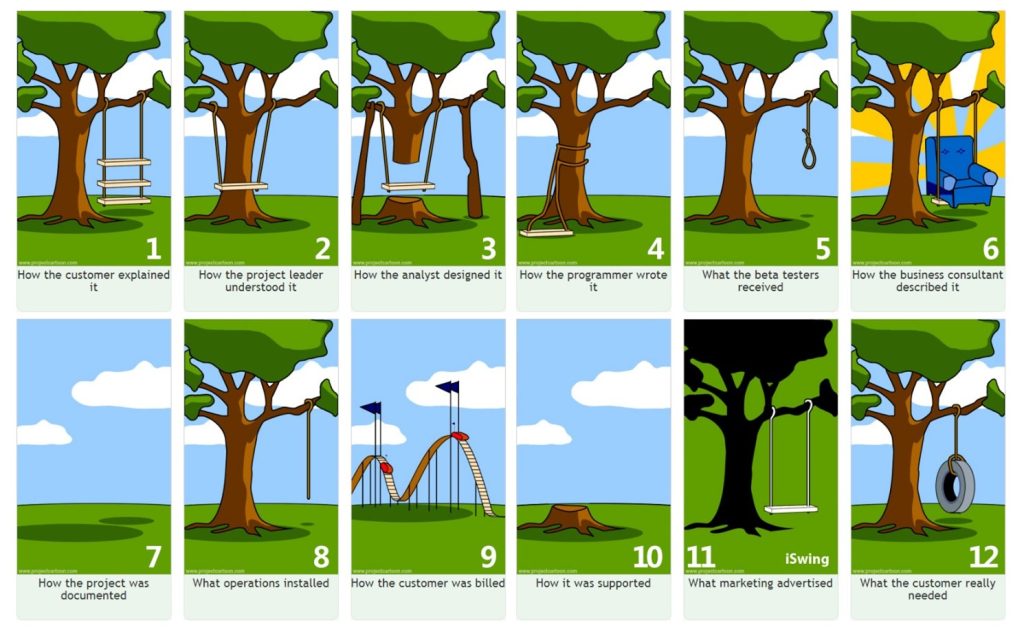

Project Synopsis

It is of utmost importance that all participants have a common understanding of the project goal(s), deliverables, and constrains in order to avoid an analogy of the famous “Tree Swing story”. For this reason, we write together with the project sponsor a so-called project synopsis as early as possible in the initiation phase.

Concept enameling plant engineering

The next step is the selection of the most appropriate enameling process, based on :

- available substrate quality

- product design

- coating requirements

- targeted production volume

Lab tests are sometimes performed to verify the achievable surface quality with the chosen enameling process.

The required enameling equipment may be specified once the enameling process is confirmed. Potential vendors are identified and reviewed. Quote requests are submitted and received quotes evaluated.

During this phase we also draft a preliminary plant layout, based on the designated material flow within the factory and individual equipment dimensions.

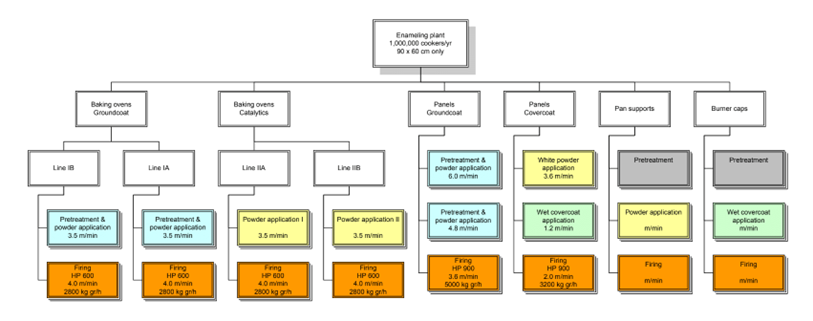

Work Breakdown Structures

It is recommended to break down complex and/or large projects into smaller work packages to ensure better planning, budgeting & quality control.

The WBS outline is drafted during the initiation phase and is gradually filled with more details during the preparation phase.

The required level of details for such Work Breakdown Structure depends upon the project size & phase.

The WBS of large enameling plant projects, like the example shown above, might have 5 or 6 levels of details, depending upon the complexity of the involved equipment.

Project planning

Our project planning consists respectively of milestones, tasks lists, tasks and subtasks, which should all be in accordance with above mentioned project phasing & WBS.

Green field enameling plants are usually an important sub project within a much larger project.

In such situation, it is important that the design of building, specification of required utilities and selection appropriate enamel technology & related equipment is carefully synchronized.

We have witnessed several projects, where the building floor was already finished without the necessary sewers for industrial wastewater.

Project implementation at existing production facilities poses other challenges because such projects are typically more time sensitive & may not affect eventual ongoing nearby production.

Project management software

Appropriate project management software should be used for planning all tasks & monitoring its progress.

Don’t use a spreadsheet for project planning, because it won’t let you identify the critical path by calculating the accumulated duration of dependent tasks.

Utilizing too many resources on non-critical tasks is an important reason for major project budget overruns.

Over the years we used and/or tested various software packages, such as Microsoft Project, Graneda Light, PMSI’s Risk+, Project Partner, Timeline Guide maker, Project Libre and many others.

In our opinion, most of those software packages are not easy to use and mainly focused either on project planning or budgeting.

It is recommended to use advanced project management software, like Zoho Project, to maintain a holistic overview during all project phases and share essential information among various team members.

Change request management

A formal process for managing change requests after project initiation is also critical, because any major change may affect the project planning, budget and/or quality.

Especially the introduction of new product (dimensions), altered production volumes and/or coating requirements after the start of your project should be thoroughly scrutinized to identifying potential risks.

Conclusion

Implementation risks of enameling plant projects may be greatly reduced by early involvement of independent subject matter experts and embedding professional project management.

Ditmer Enameling Technology is specialized in setting-up enameling plants and may provide the necessary know-how, independent advice, hands-on support & professional project management, based on almost 40 years of experience. Click here for our reference list.

In some cases, we were even contracted to deliver the entire enameling plant as a (modified) turnkey project.

Related posts

Posts about enameling projects

- How to set-up an industrial enameling plant ?

- Importance of process validation

- Second hand enameling plant for cast iron cookware

- Technical paper for upcoming International Enamellers Congress

- New enameling plant for Weber-Stephen

- Reshoring & nearshoring production

- Wet enameling plant for heat exchangers

- Automatic enameling plant for water heaters

- Successful implementation of industrial enameling plant projects

- Setting-up new enameling plants