Every industrial enameling plant has at least one enameling furnace and its design & performance has great influence on the enamel quality and cost.

Below an outline of the discussed topics:

Introduction to enameling furnace technology

Curing or firing a porcelain (vitreous) enameling coating is done in high temperature enameling furnaces.

In the early days these enameling furnaces were made of refractory bricks, due to the required firing temperature between 800 and 850 degrees Celsius.

However, such bricks are sensitive for thermal shocks and need to be heated up & cooled down very slowly.

Modern enameling furnaces are nowadays therefore made of Low Thermal Mass insulation materials, like rockwool, vermiculite & ceramic fibers.

The possibility to switch off a LTM furnace at the end of the day and heat it up again within 1 hour the next morning may provide significant annual energy savings upto 75 % in comparison with the old brick-lined furnaces.

Heating of enameling furnaces

Enameling furnaces are heated by either electricity, gas or light oil.

Gas and oil are usually combusted inside so-called radiant tubes to avoid that the enamel coating and the furnace interior is affected by the resulting combustion gasses, such as CO2 and H2O. (More about furnace atmosphere)

Depending upon the furnace design, combustion exhaust gasses are either evacuated thru the furnace roof or thru a steel or ceramic exhaust gas channel to the furnace preheating zone in order to increase the furnace efficiency.

The remaining energy of the combustion gases may be used for secondary processes, such as

- heating dryers

- heating the factory hall

Enameling furnace design

There is a wide variety of enameling furnace designs, which may be classified into three groups: box, intermittent & continuous furnaces.

Box furnaces are typically used for small production volumes and/or products with extreme dimensions.

However, most enameling furnaces are equipped with an overhead conveyor, which is runs either continuous or intermittent.

In some case furnaces with intermittent operated conveyors have automatic doors in order to avoid heat losses.

Temperature profile

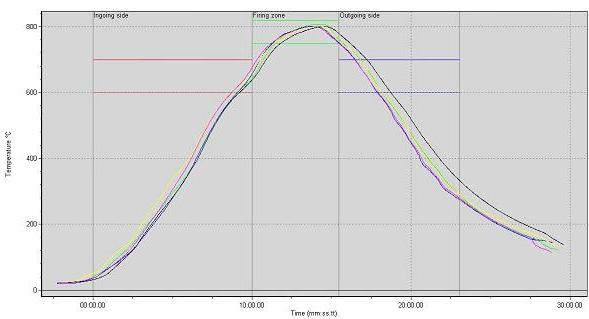

Enamels fuse and create a strong bond with the metal substrate when remaining for some minutes above its soaking temperature.

The exact holding time and soaking temperature depends upon the chemical composition of the enamel frit combination.

The primary function of an enameling furnace is to heat-up products to the soaking temperature and ensure that this temperature is maintained for at least the required holding time.

To ensure a good & repeatable enamel coating quality, it is important that the furnace’s Bozsin-box curves are smooth (to avoid thermal shocks) and show little temperature difference between the top & bottom of the products (to avoid color differences and/or wrapping).

Energy consumption

From an economical point of view, it is important that the furnace requires as little as possible energy to fire a product.

This is called the typical energy consumption of the furnace and is usually expressed as Kcal/kg or KWh/kg.

The typical energy consumption is determined by the furnace design, its heating efficiency & utilization.

Heat recovery

Gas or light oil fired furnaces are usually equipped with an internal and/or external heat exchanger to recover excess energy from the furnace exhaust gas in order to improve its heating efficiency.

The investment in an external heat exchanger only pays back, if there are other energy demanding processes near the furnace location.

Furnace conveyors

The furnace conveyor may differ from one enameling plant to the other, because its firing tools may depend on the specific product & production requirement.

Technical services

DTC may assist you with :

- Selecting the most suitable furnace design for your products & production

- Improving the firing conditions of your enameling furnace

- Reducing its energy consumption

- Extending the furnace lifetime by regular inspections & preventive maintenance.

- Converting, extending and/or relocating your enameling furnace

Below some hyperlinks to related posts about enameling furnaces: