Porcelain/vitreous enameling is a relative complex coating technology, due to the large number of (external) influences & process parameters and limited process tolerances.

Quality assurance is crucial for ensuring product reliability, compliance with standards, cost efficiency, and overall customer satisfaction.

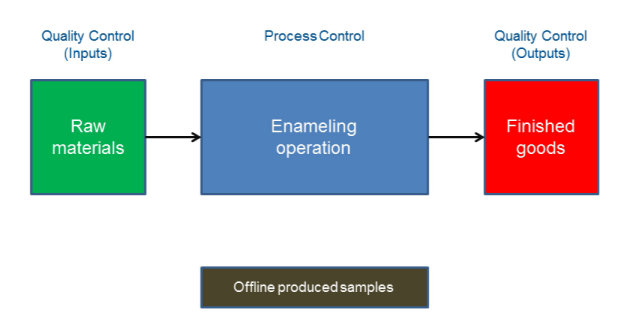

For this reason it is important to establish a framework with appropriate quality & process control measures before, during & after the enameling process.

Quality Control of incoming raw materials

The first step will be to ensure that the utilized raw materials, like enamels & metal substrate, have the desired properties.

Process Control

Depending upon the selected enameling process, an enamel plant might include 3 upto 10 process steps.

Critical process parameters & measurable influences should be continuously monitored to reduce process variances. [More about process control]

Quality control of finished goods

The used control methods & test instruments depend upon the required properties of finished goods.

The manual of the European Enamel Association provides a good overview of the applicable quality requirements & international standards per product family and a description of various test methods.

Related services

Our company may assist your with :

- Setting up a quality assurance framework

- Staff training on process & quality control

- Supplying process & quality control equipment

- Troubleshooting enameling processes & equipment

Related posts

- Automating industrial enameling processes (10/19/2025)

- New edition of EEA Quality Manual (7/13/2025)

- Major repair of old Ferro enameling furnace (3/10/2023)

- EEA Quality Requirements edition 5 (7/5/2021)

- Managing competences acc. to ISO 9001 (4/8/2019)

- Update ISO standards for porcelain enamels (12/3/2016)