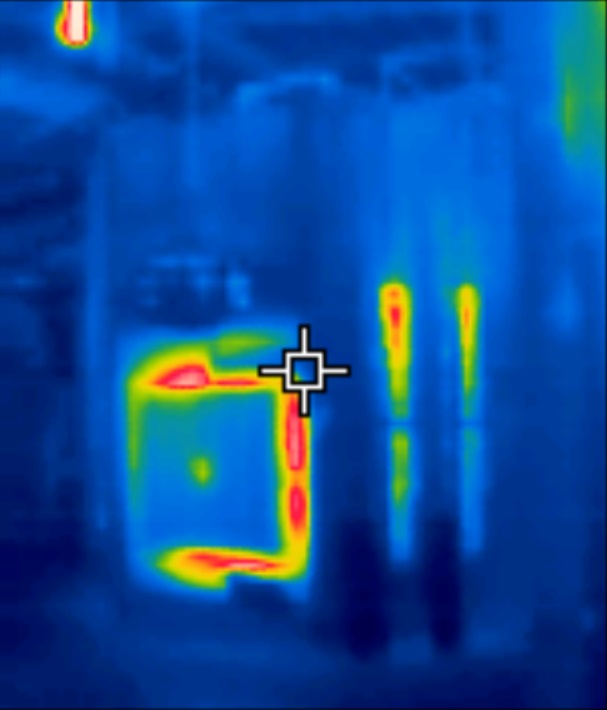

The performance of industrial enameling furnaces may gradually decline over time.

This may result in higher energy consumption (read increased enameling cost) and reduced quality of the coated surface.

In extreme cases, the enameling furnace may even unexpectedly break down because insulation has been damaged and/or worn out.

Therefore we suggest regular inspections & thermal imaging to identify major heat bridges and other spots with possible insulation issues.