A clean furnace atmosphere is important for obtaining good enameling results.

Elevated concentrations of CO2 and/or H2O may slow down the emission of gases from the metal substrate thru the enamel layer during the fusion stage and under certain unfavorable circumstances result in enameling defects such as pinholes & fish-scales.

CO2 & H2O may accumulate inside the furnace, if the combustion system is leaking and/or the forced abstraction of combustion gases is not sufficient.

Regular furnace inspections and maintenance are therefore strongly recommended.

H2O may also be inserted into the furnace atmosphere when the drying stage of a wet enamel application doesn’t work properly.

During the fusion of the enamel layer, fluorine is released.

This fluorine may react with water vapor, which is present inside the furnace and the resulting HF vapors may jeopardize furnace components made of heat resisting alloy (such as air-seals, heating elements and/or radiant tubes) and the furnace insulation.

Similar effects may occur when chlorine or potassium has been added to the milling formula of a wet enamel.

This phenomena is particularly visible at the internal air-seals, which are near the furnace hot zone.

Limited quantities of vapors may be release to the ambient via so-called vapor exhaust holes, which are typically mounted in the roof of the furnace.

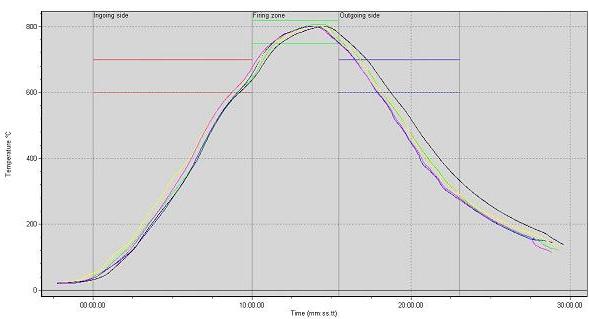

The exact position of these vapor exhaust holes is determined by the firing curve, which may be measured by means of a Bozsin-box, as shown below.

Depending upon the hourly enamel consumption and fluorine content, it might be legally required to collect all gaseous emissions and clean them by means of a fluorine scrubber.

Power enamel is porcelain enamel, which is dry milled & encapsulated with an organic coating to ensure proper electrostatic charging and to avoid tension bleeding.

This organic coating will evaporate/burn in the preheating zone of the enamel furnace.

To avoid deposition a white quartz containing layer on the firing tools, extra vapor exhaust holes need to be mounted at the ingoing side of the preheating zone.

The exact location of these vapor exhaust holes need to be determined by a firing curve too, while taking in consideration the quantity & chemical composition of the additives.