We assist manufacturers worldwide with troubleshooting industrial enameling processes & equipment

- Identify rootcause(s) of enamel defects

- Conducting independent plant audits

- Conducting independent equipment inspections

- Providing corrective & preventive maintenance advice

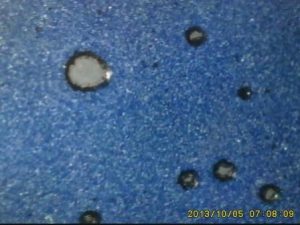

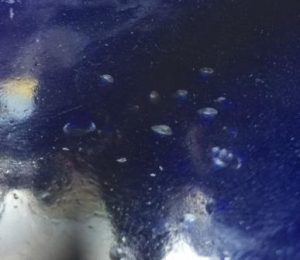

Enamel defects

Enamel defects may result in rework & in the worst case in scrapping of your almost finished goods.

In consequence it is having a great impact on your enameling cost & plant output.

Identifying the rootcause of enameling defects is not always easy.

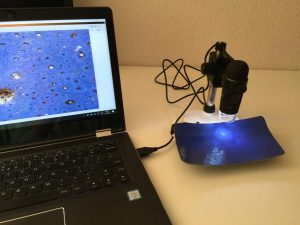

DTC may provide remote and/or on-site assistance with identification, classification & resolution of enameling defects.

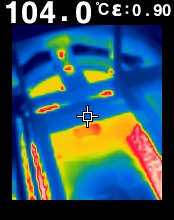

Equipment breakdown

Equipment breakdowns may effect the quality of your coating, increase your enameling cost and/or reduce the output of your enameling plant.

Regular preventive maintenance instead of corrective maintenance will reduce the chance on breakdowns.

DTC may provide independent maintenance advice based on plant/equipment inspections.