We are regularly requested to perform an enameling plant audit & equipment inspection.

Such audit is typically scheduled during the last working day of the week, so that the furnace & other equipment may also be inspected during the weekend, when cooled down.

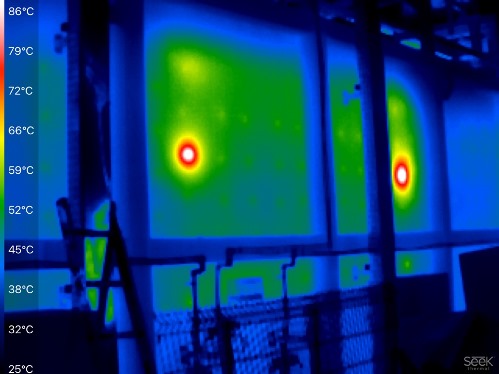

Infrared images are made during the plant audit to identify hot spots and hidden heat-bridges.

The identified heat-bridges may trigger corrective maintenance and/or energy saving initiatives.

Author

-

Ronald Ditmer is the founder and managing director of Ditmer Trading & Consulting BV.

Involved in the porcelain enameling industry since 1984 and specialized in setting-up complete enameling plants, designing enameling equipment and troubleshooting enameling processes & equipment.

View all posts