Introduction

Powder coating is an environmental friendly painting process, which provides a durable finish in a wide variety of colors & properties to thousands of products, made of either metal, wood or plastic.

Unlike traditional liquid paint applications, powder coating generate neither VOC’s nor solid waste.

The powder coating process includes only three consecutive steps: substrate pretreatment, powder application & curing.

This webpage will focus on many different aspects of powder application, powder coating equipment & industrial services provided by DTC.

Powder application process

Powder paint consist of finely ground particles of pigment & resins.

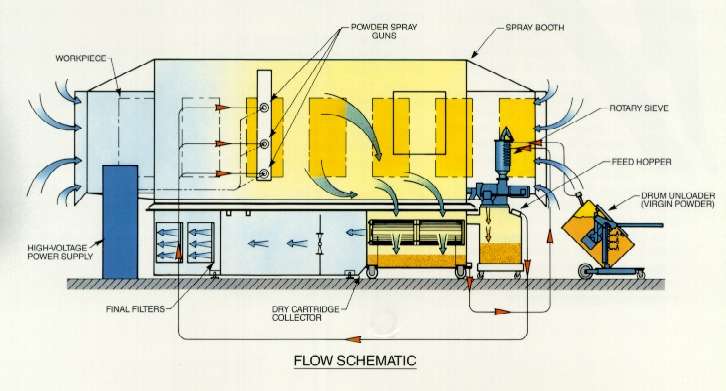

In order to secure an even layer thickness on the targeted surface, the powder is usually first fluidized (“brought into air suspension”) inside a so-called powder hopper (“powder container”).

Venturi type powder pumps are typically used to transport the fluidized powder from the hopper to the actual spraying devices.

At the sprayguns, the powder particles are charged electrostatically to achieve the highest possible transfer efficiency.

This electrostatic charge may be generated in two different ways : Tribo & Corona.

Tribo charging is done inside the powder gun and is caused by the friction between two materials with different tribo-electrical properties. In this case the individual powder particles and the gun body.

Corona charging is done within a strong electrostatic field, which is created between the electrode tip of the spraygun & the targeted object.

The transfer efficiency (TE) of a powder coating process is the reversed ration between powder sprayed & deposited on the object.

The TE is influenced by many different parameters and ranges typically between 30 and 70 %.

All powder what is not deposited on the targeted object is called “over-sprayed” and may be recycled & re-used, provided the application process take place inside a powder booth with forced abstraction.

Depending upon local legislation powder recycling may be done manually or automatic.

The ratio between over-sprayed and recycled powder is called recovery efficiency.

Mono color operations with filter recovery system have typically >99% recovery efficiency, whereas multi color/ fast color change operations with cyclone recovery range from 80 to 95 %.

Usually recovered powder is first sieved before entering into the process loop again.

Powder coating equipment

The powder application equipment is the core of every powder coating system and need to be selected with care.

Conducting pre-sales application trials are strongly recommended to discover the most suitable application equipment configuration.

Recent developments are fast color change powder coating systems, which enable switching from one color to the other within 10 – 15 minutes (with the help of 1 or 2 operators), and self-cleaning powder coating systems, which fully automatically clean the entire powder system within 7 to 10 minutes with one push on a button.

Needless to say that a fast color change time is only useful, if a good (read secure) color change can be achieved repeatedly.

Professional services by DTC

In order to achieve the lowest possible operational powder coating cost, it is important to select the right equipment which suits your products & production requirements best and comply with current & future legislation, such as the CE machine directives and ATEX directive. (Click here for other applicable norms)

DTC may help you to specify your product & production requirements, translate these requirements in minimum equipment specifications and assist you with the vendor selection process and project implementation. Please feel free to contact DTC in case you require any assistance and/or information.

Applicable norms for powder coating equipment

Industrial links**

| Related institutes | Powder coating institute, VOM |

| Powderpaint suppliers | Akzo, BASF, Becker, Dupont, Govesan, Jotun, Oxiplast, PPG, Rohm & Haas, Tiger, Worwag |

| Powdercoating equipment suppliers | Gema, KCI, Mitsuba, MS, Nordson, Parker-Ionics, Sames, Wagner, Zeus |

| Powder coating plant suppliers | Abo, Belmeko, Estee, Euroimpianti, Eisenmann, Galatek, George Koch, Glasbeek, Ideal, Indufinish, Imel, KMI, Newpac, Nutro, Rippert, Wolf, Wurster. |

** Work in progress. More companies & hyperlinks to be added in the near future. Please contact us to add your company to this list