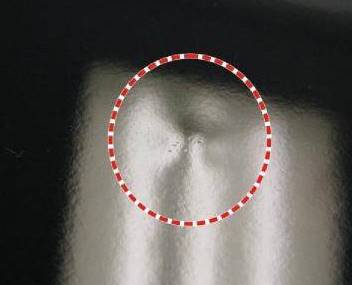

Description of defect

Lumps are common enamel defects, which are characterised by rounded raised areas with typically a diameter between 3 to 12 mm.

Occurrence

This phenomena may occur at both wet & powder enameling processes.

Possible Causes

Possible causes for lumps in random order :

- Drips of enamel slip (wet)

- Dried enamel particles falling from equipment and/or tooling (wet)

- Incorrect spray gun settings (wet)

- Worn out gun needle, nozzle or packings (wet)

- Gun spitting (powder)

- Powder deposition on gun deflectors (powder)

- Incorrect fluidity of powder enamel (powder)

- Oversized enamel particles (powder + wet)

See archive for more information about enameling defects.