Setting up a vitreous enameling plant is a major challenge for most companies, because they often lack the necessary knowledge and/or resources to complete such project successfully.

DTC may assist by providing enamel process & equipment know-how, hands-on project management support and staff training, based on more than 40 years experience within the porcelain enameling industry.

Introduction

To establish a cost effective vitreous enameling operation, the following aspects should be reviewed and defined :

- Product substrate & design

- Enameling process

- Enameling plant concept & material flow

- Enameling equipment capacity & specification

Product substrate & design

In order to achieve a good & constant enamel coating quality, it is important to comply with the existing enamel design recommendations and utilize an enamelable substrate grade.

Enameling process selection

The enameling process should be selected in accordance with the product & production requirements.

Enameling plant concept & layout

Once the enameling process has been defined, the enameling plant concept should be carefully selected.

The enameling plant concept has significant influence on the capital investment & operating cost.

Enameling equipment capacity & specification

Based on the enameling plant concept, the equipment capacity may be calculated and the minimum equipment specifications defined.

Project management

A project for setting up a vitreous enameling plant, typically consists of three stages :

- Project inception

- Project definition

- Project implementation

Project inception

During this phase the object is to confirm the technical & economical feasibility of the investment.

Project definition

This second project phase is mend to prepare as good as possible the implementation of the vitreous enameling plant.

Eventual mistakes made during this project stage are difficult to correct once the implementation has been started.

Project implementation

Upon contracting the equipment suppliers, the project implementation will commence with engineering activities.

Detailed equipment drawings will be made and the enameling plant lay-out will be finetuned.

Next all equipment components are manufactured and the factory building is prepared for the arrival of the machinery.

Once the equipment has been installed and tested, the production may be started.

Benefit from our experience

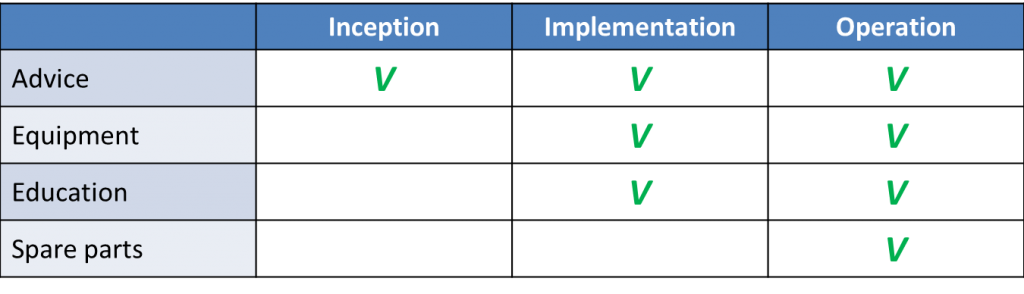

DTC may support you with advice, equipment, education and/or spare parts during the entire lifecycle of an industrial enameling plant.

As you may see on our reference list, we have been involved in more than 50 projects within the enameling industry since 1984.

Below some examples of our projects :

- Successful implementation of industrial enameling plant projects

- Modern powder enameling plant for cookers

- Wet enameling plant for cooker components

- Powder enameling plant for electrical water heaters

- Offline powder enameling plant for boilers

Please don’t hesistate to contact us to discuss your project requirements.