Below a brief overview of our services related to industrial enameling furnaces :

Concept Engineering

- New enameling furnaces

- Extension of hot zone

- Conversions from gas firing to electrical heating

- Conversions from electrical heating to gas firing

Performance Improvement

- Improving firing conditions

- Reducing energy consumption

Major Repairs / Renovations / Modifications

- Extension of hot zone

- Renovation of hot zone

- Conversion of heating system

- Installation of heat-exchanger

- Improving of air sealing

- Upgrading control system

- Relocation of equipment

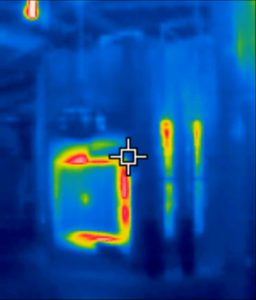

Furnace inspections

- Detection of heat losses

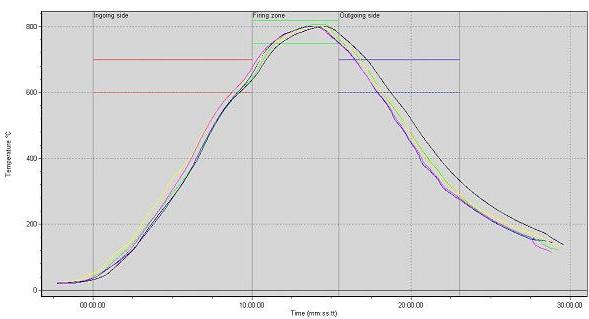

- Verification of temperature profile

- Maintenance recommendations

Supplying Spare Parts

- Ferro enameling furnaces

- Smit Ovens enameling furnaces

- Smit Sinus Enamelling furnaces

Benefit from our experience

The author joined Ferro Holland Engineering Division in 1984 and is since then involved in the design, installation, start-up, optimizing and troubleshooting of industrial enameling furnaces.

Collects temperature profiles, energy consumption & performance data of industrial enameling furnaces since the 80’s.

Helping enamellers to improve the performance of their enameling furnace, based on unique insights from practical experience & fundamental research.